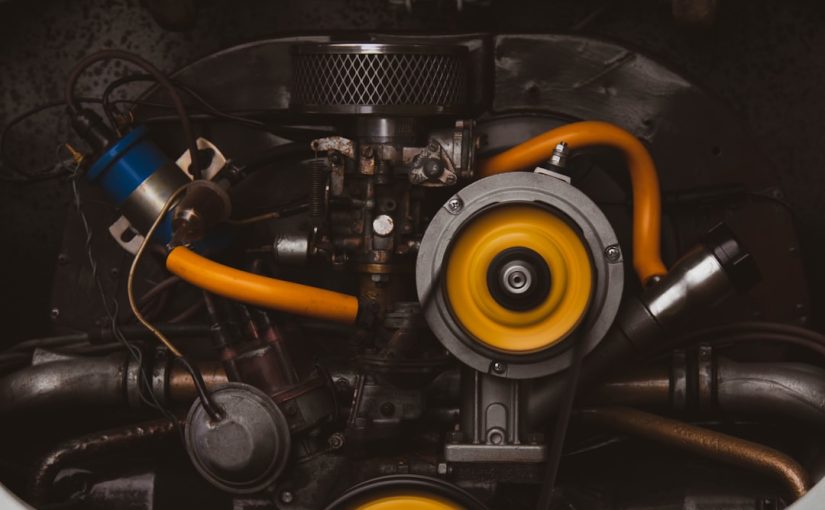

A well-maintained carburetor is the heart of any small engine, ensuring your Toro 826LE snowblower runs efficiently and reliably, especially when you need it most. Over time, fuel deposits, debris, and ethanol can clog the intricate passages of this crucial component, leading to frustrating performance issues like hard starting, rough idling, or even a complete inability to run. Understanding how to properly clean the carburetor not only restores your machine’s performance but also extends its lifespan. This guide will walk you through a detailed, step-by-step process for cleaning your Toro 826LE carburetor, covering everything from essential safety precautions and disassembly to thorough cleaning techniques and reassembly, empowering you to tackle this vital maintenance task with confidence.

Safety first and initial assessment

Before you begin any work on your Toro 826LE, prioritizing safety is paramount. Always ensure the engine is cool, disconnect the spark plug wire to prevent accidental starting, and drain the fuel tank completely into an approved container. Work in a well-ventilated area, and wear appropriate personal protective equipment, including safety glasses and gloves, to protect against fuel, chemicals, and debris. A dirty carburetor often manifests through several tell-tale signs: the engine might be difficult to start, run roughly, surge, or lose power during operation. It could also stall frequently or refuse to start altogether. These symptoms typically indicate that the fuel and air mixture is compromised due to blockages within the carburetor. Before diving into disassembly, gather all necessary tools: a set of screwdrivers (Phillips and flathead), a socket or wrench set, pliers, a catch pan for draining fuel, carburetor cleaner spray, compressed air, small wire brushes (like those found in a torch tip cleaner set), and possibly a carburetor rebuild kit containing new gaskets and o-rings, which are highly recommended for optimal sealing after cleaning.

Disassembling the carburetor with care

Locating the carburetor on your Toro 826LE is usually straightforward; it’s typically situated between the engine and the air filter housing. Begin by carefully removing the air filter housing and element to gain access. Next, you’ll need to disconnect any fuel lines, throttle linkage, and choke linkage connected to the carburetor. Pay close attention to how these are attached, perhaps even taking photos, as this will greatly assist during reassembly. Once all connections are free, unbolt the carburetor from the engine manifold. With the carburetor removed, you can begin its internal disassembly. Start by removing the fuel bowl, usually held by a single bolt at the bottom. Be prepared for a small amount of residual fuel to spill into your catch pan. Inside the fuel bowl, you’ll find the main jet, which often screws directly into the carburetor body or is part of the bowl bolt itself. Gently remove the float pin, allowing the float and needle valve to be lifted out. Accessing the pilot jet (sometimes hidden under a plug or screw) and any other adjustable mixture screws is crucial for a thorough cleaning. Keep all small parts organized; a magnetic parts tray or labeled containers can be incredibly helpful to prevent loss and ensure proper reassembly.

Thorough cleaning of components

With the carburetor fully disassembled, it’s time for the meticulous cleaning process. Use a high-quality carburetor cleaner spray to thoroughly saturate all metal components, paying special attention to the fuel bowl, main jet, pilot jet, and any air or fuel passages. Avoid spraying rubber or plastic components directly with harsh chemical cleaners, as this can degrade them. Allow the cleaner to soak for the manufacturer’s recommended time to break down stubborn varnish and deposits. Using the small wire brushes, carefully clean out the tiny orifices and passages within the jets and the carburetor body. The main jet and pilot jet often have incredibly small holes that are prone to clogging, and these must be completely clear for proper fuel flow. After scrubbing, use compressed air to blow out all passages and dry the components completely. This step is critical for dislodging any remaining debris and ensuring no cleaner residue is left behind. Inspect all components for wear or damage, particularly the float for leaks, the needle valve for grooves, and any gaskets for cracks or tears. If you have a rebuild kit, now is the time to replace these worn parts, which will ensure a proper seal and reliable operation.

Here’s a quick guide for common cleaning focus areas:

| Component | Common Issue | Cleaning Focus | Tools for Cleaning |

|---|---|---|---|

| Main Jet | Restricted fuel flow, engine runs lean at high RPM | Tiny central orifice, side holes | Small wire (torch tip cleaner), compressed air |

| Pilot Jet | Rough idle, hard starting | Very small orifices | Smallest wire, compressed air |

| Fuel Bowl | Sludge/varnish buildup | Inner surfaces, bowl bolt passage | Carburetor cleaner, brush |

| Float Needle | Fuel overflowing, engine flooding | Tip for wear, seat inside carburetor | Inspection, carburetor cleaner (for seat) |

| Fuel Passages | Overall poor performance | All drilled pathways within carburetor body | Carburetor cleaner, compressed air |

Reassembly and testing

With all components thoroughly cleaned and inspected, begin the reassembly process. If you purchased a carburetor rebuild kit, install the new gaskets and o-rings now, ensuring they are seated correctly. Carefully reinsert the needle valve and float, securing it with the float pin. Install the main jet, pilot jet, and then reattach the fuel bowl, tightening the bolt to the manufacturer’s specifications—avoid overtightening, which can damage gaskets. Once the carburetor is fully assembled, remount it onto the engine manifold, ensuring a snug fit. Reconnect all fuel lines, throttle linkage, and choke linkage, referring to any photos you took during disassembly if needed. Double-check all connections for security. Refill your Toro 826LE’s fuel tank with fresh, stabilized gasoline. Reconnect the spark plug wire, and you’re ready to test. Start the engine and listen for smooth operation. Allow it to warm up, then check for any fuel leaks around the carburetor. If the engine isn’t idling correctly, you may need to make minor adjustments to the idle mixture screw (if your model has one) or the idle speed screw until it runs smoothly. A successful cleaning will result in improved starting, smoother running, and optimal performance from your snowblower.

Cleaning the carburetor on your Toro 826LE snowblower is a detailed but rewarding maintenance task that significantly impacts your machine’s performance and longevity. By carefully following the steps outlined, from prioritizing safety and meticulously disassembling components to thoroughly cleaning each passage and reassembling with care, you can resolve common fuel-related issues. We’ve covered the critical importance of a clean carburetor, the specific steps for disassembly, effective cleaning techniques using specialized tools and solutions, and the essential reassembly process for optimal function. Remember, patience and attention to detail are your best assets throughout this process. Regular maintenance, including the use of fresh, stabilized fuel, can prevent future clogs and ensure your Toro 826LE is always ready to tackle heavy snowfall, providing reliable service season after season. Empower yourself with this knowledge, and keep your snowblower running like new.

Image by: Lucas Larsson