Tired of generic garden center planters that lack personality? Imagine crafting stunning, one-of-a-kind vessels that perfectly complement your outdoor oasis, all while being incredibly durable and surprisingly simple to create. This guide will unlock the secrets to making beautiful outdoor planters entirely from sand, transforming a humble material into a resilient and aesthetically pleasing home for your plants. Beyond just a DIY project, this endeavor offers a chance to infuse your garden with unique textures and shapes, providing a custom touch that store-bought options simply can’t match. We’ll delve into the necessary materials, crucial mixing techniques, creative molding processes, and the vital steps for curing and finishing, ensuring your sand planters stand the test of time and weather.

Understanding the materials and preparation

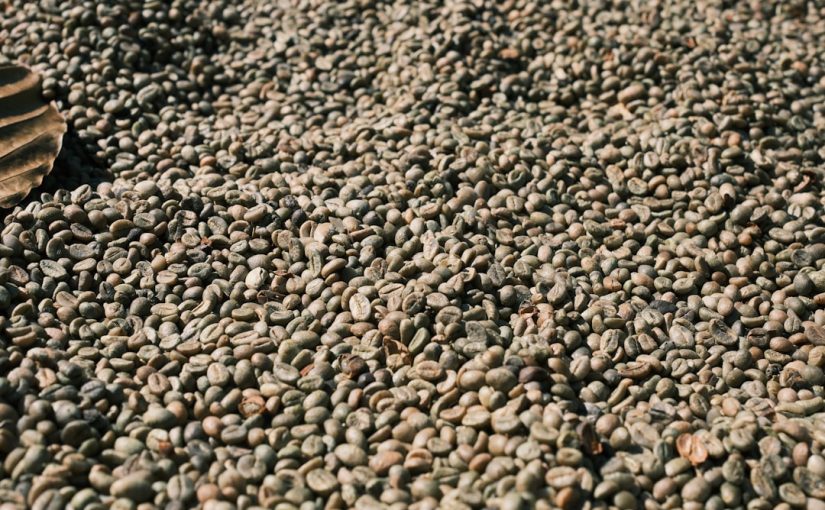

Before embarking on this rewarding project, gathering the right materials and understanding their roles is paramount. The foundation of your sand planter is, naturally, sand itself, but not just any sand will do. For structural integrity, builder’s sand or sharp sand is generally preferred over play sand. Builder’s sand has varied particle sizes and rougher edges, which allows for better interlocking when mixed with cement, creating a stronger composite. Play sand, being finer and more uniform, might result in a weaker structure. The binding agent is typically Portland cement, a hydraulic cement that hardens when mixed with water and aggregates. The quality and freshness of your cement are crucial for the planter’s final strength.

You will also need water, which activates the cement and helps achieve a workable consistency. Molds are essential for shaping your planter; these can range from repurposed plastic containers, buckets, or even cardboard boxes lined with plastic sheeting. For larger or more intricate designs, consider incorporating a reinforcing mesh, such as chicken wire or fiberglass mesh, especially if the planter will hold a significant amount of soil. Essential tools include a sturdy mixing tub or wheelbarrow, a shovel or hoe for mixing, a trowel, and a pair of gloves and safety glasses for personal protection. Proper preparation ensures a smooth and safe creation process.

Mixing the sand cement composite

The success of your sand planter hinges significantly on achieving the correct mix ratio and consistency. A common starting point for a durable, yet workable, sand cement composite is a ratio of 3 parts sand to 1 part Portland cement. Some projects might even tolerate a 4:1 ratio for a slightly lighter or less dense finish, but 3:1 offers a good balance of strength and manageability for planters. Begin by thoroughly dry-mixing the sand and cement in your mixing tub or wheelbarrow until the color is uniform, indicating an even distribution of materials. This is a critical step, as inconsistent mixing can lead to weak spots in your finished planter.

Once dry-mixed, gradually add water, little by little, while continuously mixing. The goal is to reach a consistency often described as “earth-moist” or like damp sand – it should hold its shape when squeezed but not be excessively wet or runny. Too much water weakens the final product significantly and can lead to excessive shrinkage and cracking during curing. Too little water, conversely, makes the mix difficult to work with and may prevent proper hydration of the cement. It’s better to err on the side of slightly drier and add minimal amounts of water incrementally. The mixture should be cohesive enough to be packed firmly into a mold without crumbling, but not so wet that it slumps or has standing water. Patience during this mixing phase will pay dividends in the strength and appearance of your finished planter.

Shaping and molding your planter

With your sand cement composite perfectly mixed, the creative process of shaping your planter begins. There are two primary molding techniques for planters: the single-mold method and the double-mold method. The single-mold method involves packing the mixture into an existing container, forming the outer shape of your planter. This is simpler but results in a solid, heavier planter, with the hollowed-out area for soil needing to be created post-curing or by pressing a smaller object into the wet mixture. The double-mold method, however, is generally preferred for planters as it directly creates the inner and outer walls, resulting in a hollow structure from the outset.

For the double-mold technique, you’ll need two containers of different sizes – an outer mold and an inner mold, with a sufficient gap between them to form your planter wall (typically 1-2 inches). Liberally apply a release agent (such as cooking oil, petroleum jelly, or a commercial mold release spray) to the inside of the outer mold and the outside of the inner mold. This prevents the sand cement from sticking. Begin by packing a layer of the mixture at the bottom of the outer mold to form the base of your planter. Firmly press the inner mold into this base layer, ensuring it’s centered and suspended to maintain even wall thickness. Then, systematically pack the sand cement mixture into the gap between the two molds, pressing firmly to eliminate air pockets and ensure a dense, strong wall. Remember to create drainage holes at the bottom of your planter using a dowel or a piece of PVC pipe inserted into the wet mixture; these are crucial for plant health. Allow the mixture to set for several hours before carefully removing the inner mold, then the outer mold, typically after 24-48 hours, depending on ambient conditions.

Curing and finishing touches

The most crucial stage after molding is curing, a process often overlooked but vital for the planter’s ultimate strength and durability. Curing isn’t just about letting the planter dry; it’s about allowing the cement to hydrate fully and chemically bond with the sand particles. This process takes time and requires consistent moisture. For the first 7-10 days, it’s essential to keep your newly demolded planter consistently moist. You can achieve this by periodically misting it with water, covering it with a plastic sheet to trap humidity, or even submerging it in a shallow bath of water (though ensure the water isn’t too cold). Proper curing prevents premature drying, which can lead to cracking, crumbling, and a weaker final product. The majority of the cement’s strength develops within the first 28 days, so patience is key.

Once fully cured, your sand planter might have some rough edges or minor imperfections. These can be smoothed out using sandpaper or a sanding block for a more refined look. For added longevity and to prevent efflorescence (the white powdery residue that sometimes appears on concrete), consider applying a concrete sealer. There are various types of sealers, from penetrating to topical, each offering different levels of protection and aesthetic finish. Some sealers can enhance the natural color of the sand and cement, while others provide a matte or glossy look. This final sealing step helps protect against weathering, moisture absorption, and general wear and tear, ensuring your handcrafted sand planter remains a beautiful and functional addition to your outdoor space for years to come.

| Sand-to-Cement Ratio (by volume) | Water Content (Approx.) | Characteristics & Recommended Use |

|---|---|---|

| 3:1 | Minimal, “earth-moist” | Strongest, most durable. Ideal for larger planters, high-traffic areas, or designs requiring maximum structural integrity. |

| 4:1 | Minimal, “earth-moist” | Good strength, lighter. Suitable for medium-sized planters, decorative pieces, where slight weight reduction is desired without sacrificing much strength. |

| 5:1 | Minimal, “earth-moist” | Moderate strength, lighter. Best for small, non-load-bearing planters or purely decorative items. May require reinforcement for larger forms. |

Embarking on the journey to create outdoor planters from sand is a uniquely rewarding DIY project, offering a blend of creativity, sustainability, and personal satisfaction. We’ve explored every critical stage, from meticulously selecting the right sand and cement to mastering the art of mixing, shaping with molds, and ensuring the vital curing process for longevity. The result is not just a planter, but a testament to your ingenuity and a truly custom piece that store-bought options simply cannot replicate. These sand planters provide exceptional durability against the elements, a natural aesthetic that complements any garden, and the pride of knowing you built it with your own hands. Remember to prioritize safety, embrace patience, and allow your creativity to flourish. By following these steps, you’re not just making a planter; you’re crafting a lasting piece of your outdoor narrative, ready to nurture your favorite plants for seasons to come.

Image by: Duc Van